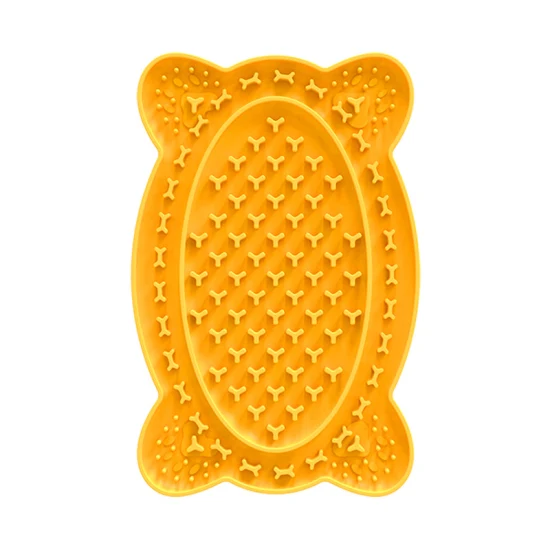

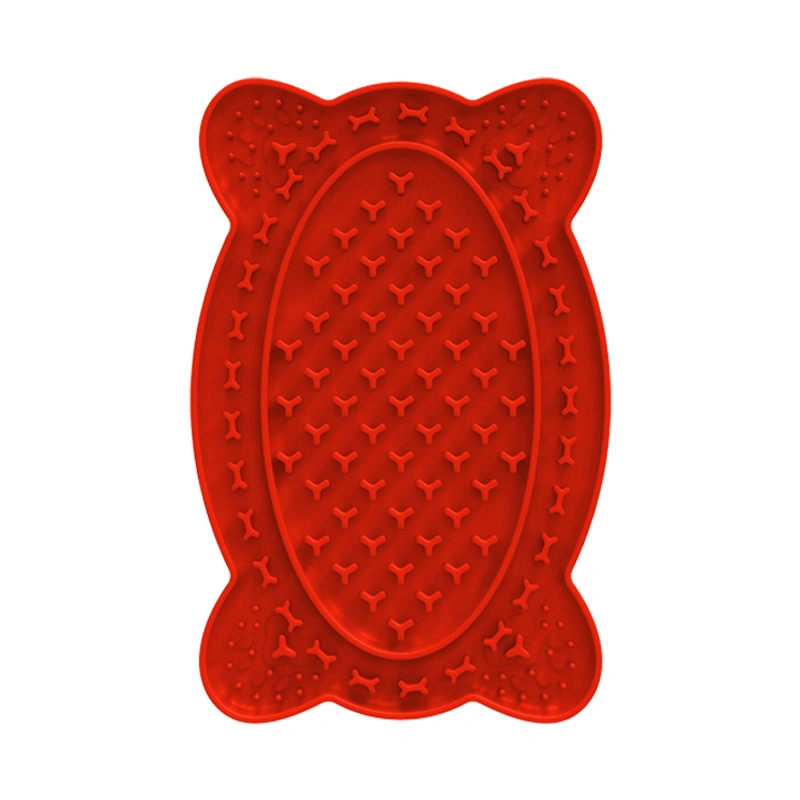

Silicone Dog Licking Tray Pet Bathroom Slow Food Mat FDA Silicone Dripping Licking Pad Pet Suction Tray Slow Feeder Lick Pat with Non

Silicone Dog Licking Tray Pet Bathroom Slow Food Mat FDA Silicone Dripping Licking Pad Pet Suction Tray Slow Feeder Lic;

Basic Info.

| Model NO. | silicone pet licking tray |

| Certification | FDA |

| Color | Yellow, Green, Black, Red, Blue |

| Fixed Time Feeding | Without Fixed Time Feeding |

| Customized | Customized |

| Colour | Yellow, Green, Blue, Red, Sky Blue |

| Additional Function | Anti-Slip Bottom |

| Transport Package | Carton |

| Specification | 127*196mm |

| Trademark | OME |

| Origin | Dongguan, China |

| Production Capacity | 2000pieces/Year |

Product Description

| Product Description | ||

| Products | Name | silicone pet licking tray |

| Products category | rubber molded product | |

| Material | Organic silicone | |

| Size | 127*196mm | |

| Shape | capable of all shapes as per drawing | |

| Color | Natural,black, Pantone code or RAL code, or as per client's samples or requirements | |

| Hardness | 20°~90° Shore A, usually 30°~80° Shore A. | |

| Surface finishing | Texture (VDI/MT standard, or made to client's sample), polished (high polish, mirror polish), smooth, painting, powder coating, printing, electroplating etc. | |

| Drawing | 2D or 3D draiwng in any image/picture format is OK | |

| Free sample | Yes | |

| OEM/OEM | Yes | |

| Application | Household, electronics, for vehicles like GM, Ford, Honda. Machinery, hospital, petrochemical, Aerospace etc. | |

| Market | Europe, North America, Oceania | |

| Quality certification | FDA, REACH, ROHS, SGS | |

| QC | Every order production will get more than 10 times regular check and 5 fives times random check by our professional QC. Or by Third party appointed by customer | |

| Mold | Molding Process | Injection molding, mold processing, extrusion |

| Mould type | processing mold, injection mold, extrusionmold | |

| Machines | 350T vacuum pressing machine and other pressing machine at 300T,250T and so on | |

| Tooling equipment | Rubber tension tester, Rubber vulcanization instrument, Durometer, calipers, ageing oven | |

| Cavity | 1~400 cavities | |

| Mould Life | 300,000~1,000,000 times | |

| Production | Production capacity | finish each mold of product in 3 minutes and working on 3 shifts within 24 hours |

| Mold lead time | 15~35 days | |

| Sample lead time | 3~5 days | |

| Production time | usually 15~30 days, should be confirmed before order | |

| Loading port | shenzhen,dongguan,guangzhou or as required | |

You may also like

Send inquiry

Send now